- Location:

- Home

- Products

- VS Sensorik spindle encoders

VS Sensorik GmbH (hereinafter referred to as VS) is a leading European company for magnetic sensing products with a history

of nearly thirty years and a focus on technology development. The headquarters are located in Bielefeld, North Rhine-Westphalia,

Germany.

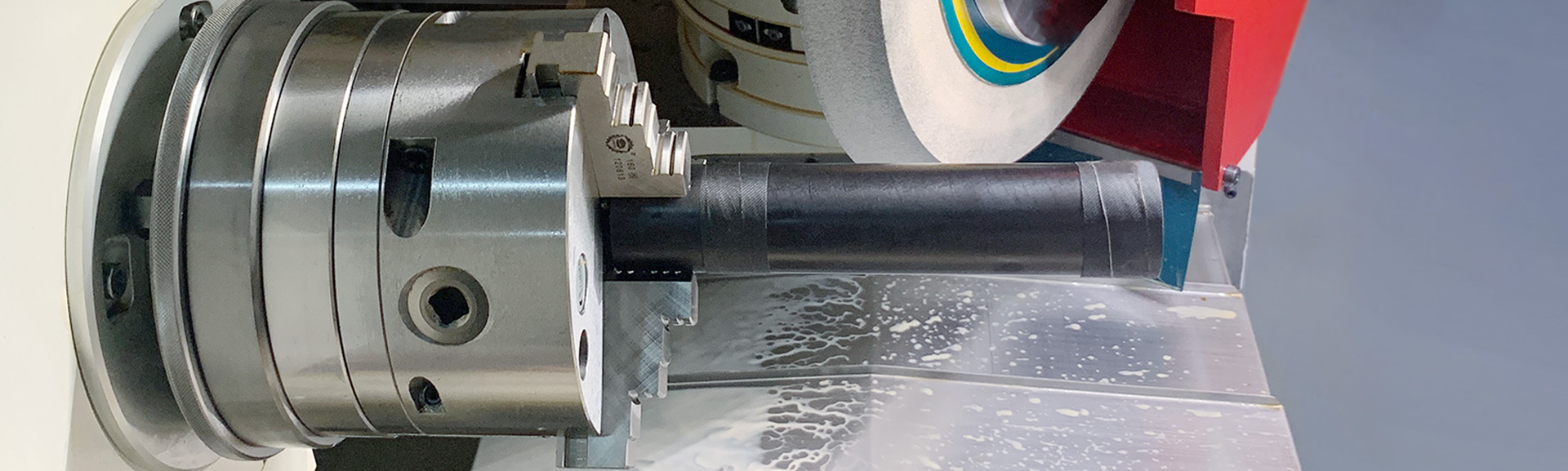

VS Sensorik develops sensors based on electromagnetic theory for various industrial applications, especially for incremental/absolute

measurement of spindle speed and angular position in precision machine tools. and absolute encoders for the measurement

of distance, angular velocity and vibration in demanding industrial environments (e.g. construction machinery, aviation, automotive, etc.).

The company is a member of the VS Sensorik family of companies.

Bonsing is the only strategic partner of VS Sensorik in China and is responsible for the sales and technical service of VS Sensorik

in the Greater China region. We are responsible for the sales and technical service of VS Sensorik in China:

http://www.vs-sensorik.com/sales-partners.html

Important stages in the development of VS Sensorik Germany:

In 1993, VS Sensorik GmbH was founded in the high-tech industrial district of Munich, Germany. In 1993, VS Sensorik GmbH was

founded in the high-tech industrial district of Munich, Germany, to provide high-performance and reliable encoders, sensors and

technical solutions efficiently and quickly. and technical solutions.

In 1994, the first series of encoders (product line RGK2M ) were successfully used in machine tool spindles for measuring speed

and position. The first series of encoders (RGK2M) were successfully used in machine tool spindles to measure speed and position.

In 1997, the first world-leading "magnetic proximity switch" for the hydraulic system of concrete pumps was developed. This product

has unparalleled pressure resistance and is used in large quantities in the construction machinery sector. For example, the German

construction machinery manufacturer Putzmeister.

In 1999, magnetic pulse encoders with "code discs" as signal receivers (product series MGD, HDI2) were used in the electric vehicle

industry. in the electric vehicle industry.

In 2007, the product series RGM2G was embedded with GMR (Giant Magnetoresistance) modules with ESD Stability up to 30 kV,

The encoder can be programmed and controlled using the I2C interface.

In 2008, a portable measuring box with USB function for calibration and measurement of encoders was developed: DCMU-BOX,

which It can analyze and measure the analog sine/cosine encoder signals online up to 60,000 rpm.

In 2009, a cooperation with a leading German robotics company was initiated.

In 2010, development of 3D position magnetic induction encoders for robotic applications begins, and in the same year the

companymoves its location to North Westphalia, Germany. North Westphalia in the same year.

In 2012, the company was certified as an IHK product.

VS Sensorik encoders have been trusted by our partners for many years in the following areas:

Construction machinery: Putzmeiser's supplier of robust and reliable sensors, resistant to high pressure applications

Machine tool industry: high precision, high dynamic tracking

Special machinery: reliable, high precision, long-lasting operation at high temperatures

Aerospace industry: Reliable, stable products at extreme temperatures

Military industry: robust quality, reliability, high precision

Hydraulic system: durable and stable, with strong resistance to pressure

scientific and technological research and development qualifications.

The following are some of our important customers: