- Location:

- Home

- Products

- SKF ultra-precision bearings

SKF offers ultra-precise angular contact ball bearings with a wide range of design features:

1, SKF ultra-precision angular contact ball bearings are classified by size type:

718 Ultra light series: applications with small cross-sections

719 Very light series 70: applications with large radial space and light loads

72 Reinforced series: Large cross-section for applications with heavy loads and low speeds

2, three different contact angles: 15° contact angle, model number suffix C; 25° contact angle,

model number suffix AC; 18° contact angle, model number suffix F

3, Different ball sizes: high load D design; high speed E design; high speed W design; high speed B design

4, two kinds of unused ball materials (mixed ceramic balls)

5, Multiple Sealing Options

The most common bearings available are equipped with integral seals (model prefix S) on both sides, which

form an extremely narrow clearance (as shown below), so that speed is not affected.

These steel plate reinforced seals consist of Nitrile Buna N (NBR) which is oil and wear resistant as a standard

material. Upon request, the The seals of the bearings can also consist of fluoroelastomer (FKM).

As standard, after sealing, these bearings are filled with a high-quality, low-viscosity grease based on a synthetic

ether with a lithium-based thickener. The grease is filled to 15% of the free space inside the bearing. The operating

temperature of the grease is between -55 and 110°. Upon request, the Bearings can also be lubricated with other

greases.

Sealed bearings offer the following benefits over bearing configurations containing start bearings and

external seals:

Potential for longer bearing life

Extended maintenance intervals

Reduced inventory

Reduced risk of lubricant contamination during mounting and operation

Sealed bearings get lifetime lubrication. Such bearings should never be cleaned and should not be heated above

80°C (175°F). If it is necessary to heat the sealed bearing during installation, an induction heater must be used

and the installation should be done immediately to minimize the time the bearing is exposed to high temperatures.

For storage of sealed bearings, please refer to the following information.

Storage conditions: Store the bearings flat, the storage room must be free of vibration and dust, pending

and rust The bearings that are not stored in their original packaging should be well protected from rust and

dust.cooling system and stable temperature; according to the following requirements Control and limit the

temperature of the storage room: 20℃ (68℉) humidity 75%, 22℃ (72℉) humidity 60%, 25℃ (77℉) The

bearings should remain in their original unopened packaging until installation to prevent contaminant ingress

Bearing storage period: Before leaving the factory, SKF bearings are coated with rust inhibitor and properly

packaged. For open type bearings, if the storage If the storage conditions are suitable, protective measures

can ensure that in about three years of time textile bearing rust.

The maximum storage period of sealed bearings: The maximum storage period of SKF sealed bearings is

determined by the lubricant inside the bearing. Due to ageing, solidification and Due to aging, solidification

and separation of base oil and thickener, the lubricant will deteriorate with time. Therefore, the storage

period of sealed bearings should not exceed three years.

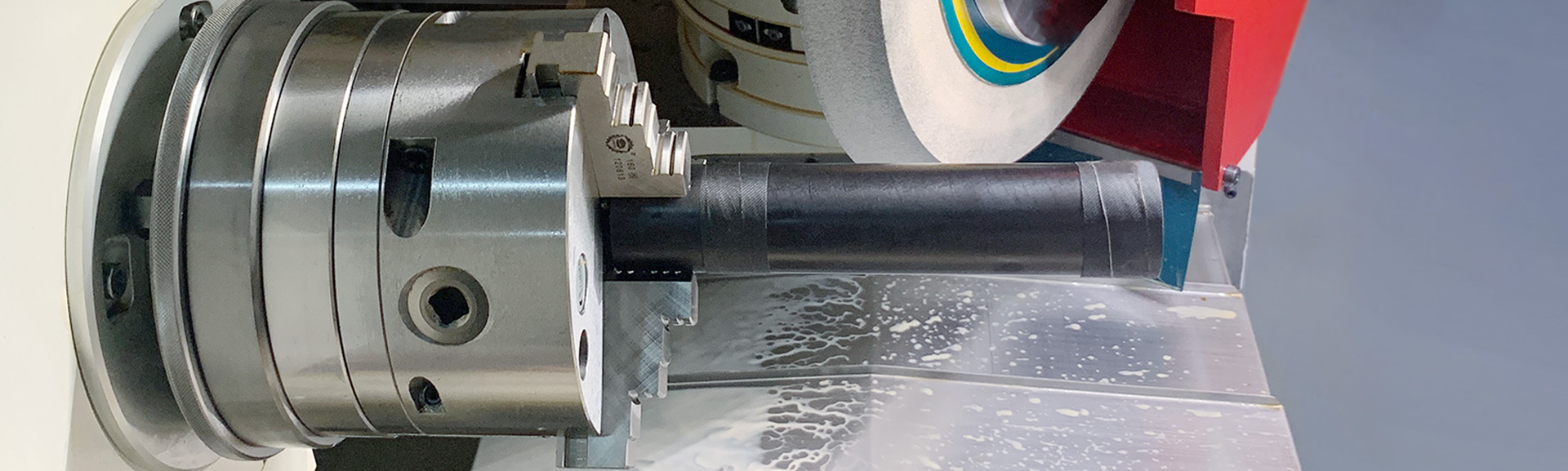

6, Direct oil-air lubrication

Some very high speed applications require the 719...D and 70...D series, the 719...E and 70...E series,

and the 719...B and 70...B series open B and 70...B series, use a minimum amount of oil and are lubricated

directly through their outer rings.