- Location:

- Home

- Products

- Oil and gas lubrication system

SKF lubrication systems for precision machine tools

As the world leader in centralized lubrication systems, SKF offers components, assemblies, and complete

lubrication systems for machine tools, printing presses, general machinery, and applications in construction

vehicles and railroads. SKF offers components, assemblies, and complete lubrication systems for machine

tools, printing presses, general machinery, and construction vehicles and railroad applications.

Product categories include:

Full consumption centralized lubrication system

Circulating oil lubrication system

Micro-lubrication system

Chain lubrication system

SKF systems are designed to meet the lubrication needs of the latest generation of high-speed machines

and to avoid lubrication-related damage and failure. VOGEL oil, grease or air systems accurately measure

the amount of lubrication required and continuously monitor the lubrication condition close to the lubrication

point. The SKF system provides a higher level of efficiency in production operations and maintains proper

operating conditions for spindles and high-precision bearings.

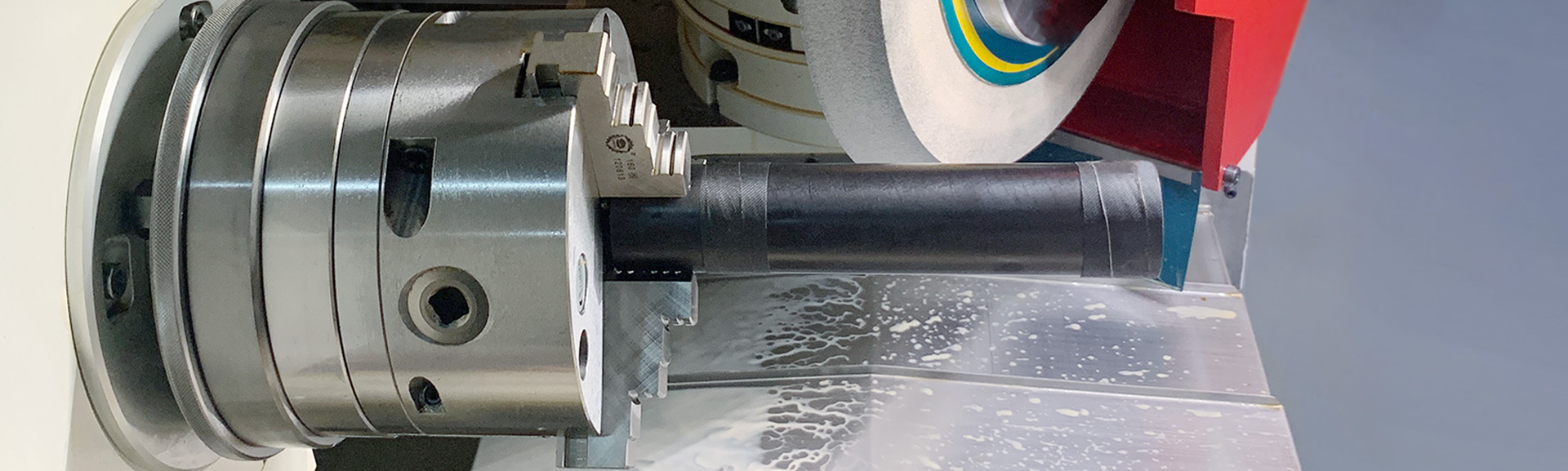

Oil and gas lubrication system

The oil-air lubrication system is a trace lubrication system. Its typical applications include: high-speed rolling

bearing boxes for machine tool spindles that require economical lubrication enclosed gearboxes.

The oil-air lubrication system provides a constant, good flow of oil, which can be adjusted to suit the needs

of different applications by controlling the flow or changing the pulsation frequency. the needs of different

applications.

Micro Lubrication (MQL)

Micro lubrication makes it possible to transfer minute amounts of cutting fluid in the machine tool. The

cutting fluid is transferred between the tool and the workpiece by means of a sprayer, i.e. there are

drops of through the air stream to create a good diffusion. This type of lubrication allows for higher

cutting speeds and ultimately higher productivity.

Other benefits include:

Longer tool life and reduced cutting fluid usage, which can significantly reduce machining costs and

reduce environmental impact. VOGEL also provides permanent monitoring of oil mist volume and

concentration through sensors.

SKF, VOGEL and other well-known companies in the field of mechanical engineering, components

and production have jointly developed the HPC standard (High Performance Cutting). By defining

By defining uniform mating surfaces and performance curves, the standard provides easy integration

of MQL.

Internal Micro Lubrication (MQL)

With internal micro-lubrication, the oil mist is transmitted through the rotating spindle or

turret via the toolholder and tool. When properly adjusted, the measured amount of oil

will completely diffused.

The MQL system consists of various regulating components that work together to lubricate

the cutting area. To meet the needs of specific applications, VOGEL offers a range of products

in different configurations, from the manually operated VARIO unit to the Digital Super unit

with stored program control.

External micro-lubrication

With external micro-lubrication, lubricant and air are injected into the active area between

the tool and the workpiece via pipes and nozzles, but the pipes and nozzles are not part

of the machine design. Therefore the nozzles have to be adjusted in different applications.

This relatively rigid system is suitable for machining operations where tool and workpiece

contours areVOGEL's basic, intelligent and Vectolub product families are well suited for

this type of work. for this type of work.