- Location:

- Home

- Products

- VS Sensorik spindle encoders

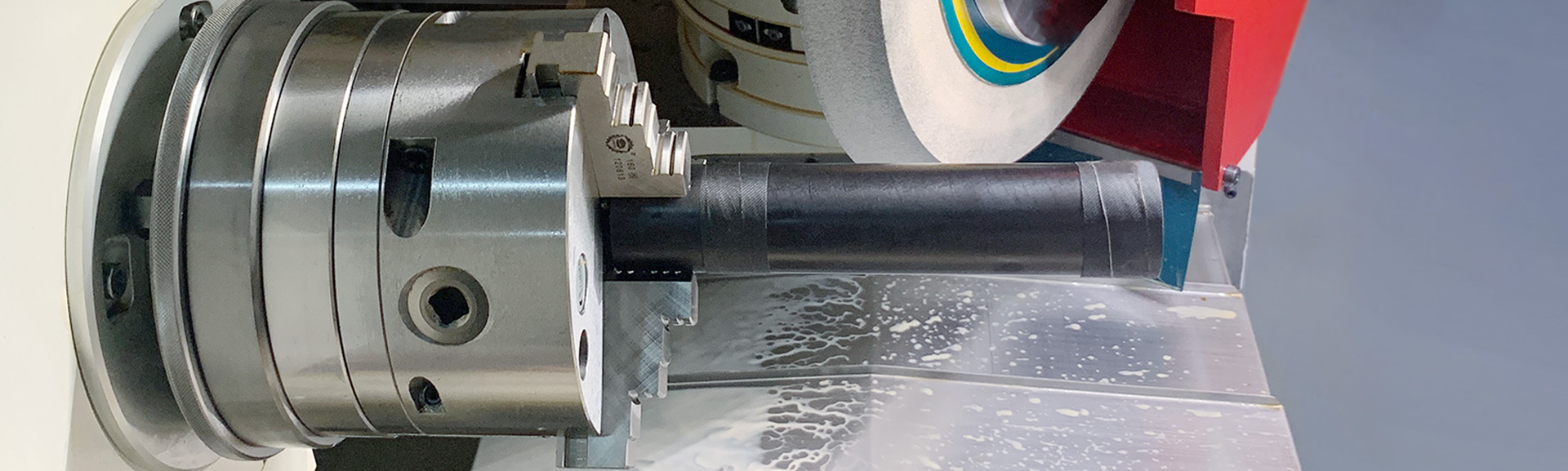

High-performance spindle incremental encoder - for synchronous motor spindles with strong

magnetic environment

VS Sensorik encoders are traditionally German: robust, precise, with excellent signal resolution, resistant to electromagnetic

interference, and particularly suitable for Electric spindles with synchronous motors (resistant to vibration, impact, ESD in strong

magnetic fields)

| Advantages and features: | |

| Electromagnetic induction work, no direct contact with the letter number plate thus avoiding mechanical wear and tear | 1Vss differential signal, very strong sine and cosine output signal |

| TTL or HTL square wave signal can be output | Uses interpolated electronic multiplication to amplify signals for a variety of controllers |

| Automatic calibration, stable amplitude | High resolution measurement of rotational speed and angle up to 100,000RPM |

| Suitable for high speed cutting applications on machine tools | Suitable for high speed cutting applications on machine tools |

| Resistant to strong magnetic and electrostatic interference (30Kv) | Full metal shell, strong, durable, not easy to scrape |

| Full metal shell, strong, durable, not easy to scrape | Can work in high temperature environment 100℃ (some products can reach 120℃, please consult our technical staff for related applications) |

| Connectable to VS measurement tools for calibration, data reading and writing | |

Solutions for machine tool spindle encoders

Encoders in working condition need to be equipped with a corresponding signal transmitter, usually with different modules and tooth counts.

In addition, we offer the following technical solutions according to customer requirements:

Code discs: available in modules M=0.3, 0.4 and 0.5, or on request.

The encoder housing is all-metal, but can be customized according to the customer's needs.

Cables for signal connection and temperature measurement are available for different control systems.

The encoder data can be collected and analyzed with VS' exclusive DCMU external encoder signal measurement box.

The encoder signal parameters can be adjusted via the PuV interface using an external device such as the HCU500 portable handheld toolbox.

The external measuring device DCMU-BOX can be used for quality control and mobile collection and analysis of the spindle operating signals

as well as for monitoring the condition (integrity) of the code plate.

VS encoders are made in Germany. Our quality products have a long service life;

We often encounter machine tool customers who find during spindle maintenance that the VS encoders have outlived many

other components but are still in use. Many other components are still in use.

As we are constantly replacing our products, please note that if you have an older encoder that needs to be replaced, please do so:

Encoders with the model numbers MGK2M, KWG2M, KWG2D, RGK2M, etc. are still available or we can help you with New and

improved products compatible with these models are available.

For the SIZAG and SIMAG series used in Siemens systems, we offer new compatible encoders.

For all

M=0.3, 0.4, 0.5 modulo discs we offer compatible solutions (size and design) for encoder readheads. This is especially true for discs with

different reference signal types.We offer

a wide range of discs in modulo M=0.8, 1.0. Solutions from dimensional design to encoder readheads (e.g. replacement of older models FP-210)

| Common encoder models | |||||

| RGM2G-A | RGM2G-AM | RGM2G-AM1 | RGM2G-AM2 | RGM2G-AS | RGM2G-AP |

| RGM2G-APS | RGM2G-AE3 | RGM2G-AMS | RGM2S-A | RGM2S-AS | RGM2S-AP |

| RGM2S-AM | RGM2S-APS | RGM2S-AMS | RGM2T-A | RGM2T-AS | RGM2T-AP |

| RGM2T-AM | RGM2T-APS | RGM2T-AMS | RGM2G-D | ROM2G-A | RGK2G-A |

| RGK2H-A | RGK2H-AA | RGK2H-AI | FGM2G-A | SGM2G-A | KHG2D |

| KHG2D(S) | KHG2D(T) | KHG2D(H) | KWG2D | KWG2H | SIMAG |

| SIZAG | WOELKE | ||||