- Location:

- Home

- Products

- Oil and gas lubrication system

Improve reliability, simplify maintenance and reduce environmental impact

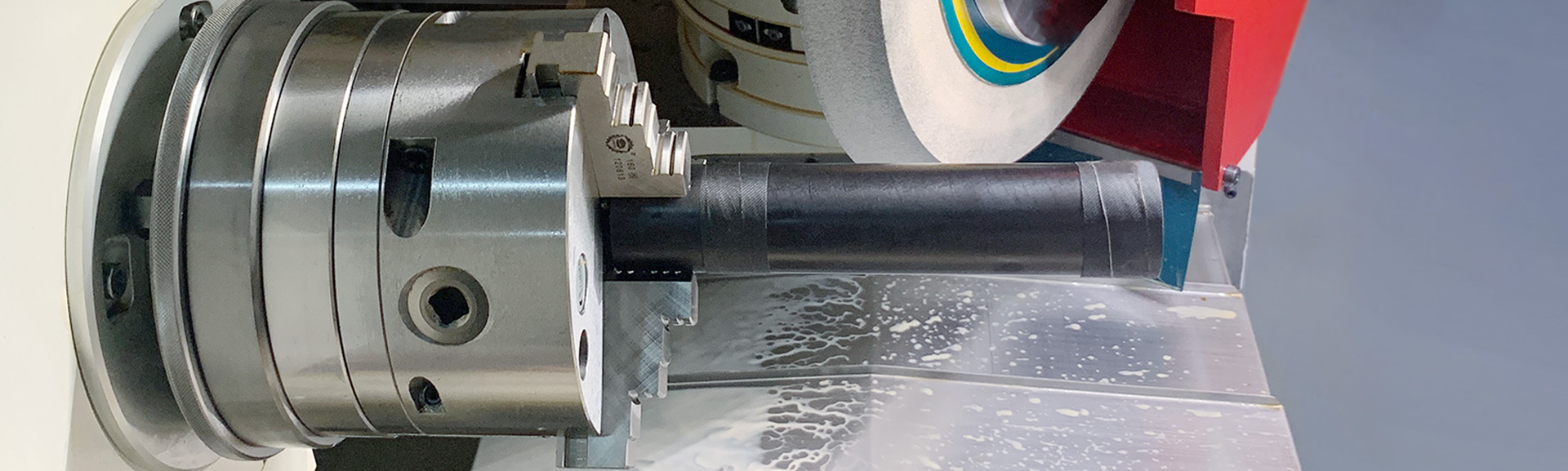

To meet increasing performance requirements for high-speed precision applications, SKF has developed

a new ultra-precision bearing lubrication unit that available for oil and gas lubrication in high-speed

applications. This system simplifies new spindle designs and can improve the performance of existing

designs.

This efficient solution improves lubricant flow, reduces heat generated by bearing friction, and allows

bearings to operate at speeds up to approximately 250 -3 million ndm. While reducing operating

temperatures and improving oil and gas lubricant flow, it also reduces oil consumption and noise

levels. The solution also reduces oil consumption and noise levels.

Advantages of oil-air lubrication:

The speed at which a bearing reaches its operating temperature limit depends first and foremost

on the heat generated by the bearing and the heat that can be removed from the bearing. In order

to reduce frictional heat especially in the bearing, this can be achieved by ensuring that the required

components are supplied with the exact amount of lubricant at the right time. Many high-speed

applications applications can be lubricated by grease. However, as operating temperatures and the

resulting frictional heat increase, grease is often replaced by oil lubrication systems. The grease is

often replaced by an oil lubrication system.

Very high-speed applications often require a precise lubricant delivery system: an oil-air lubrication

system can continuously deliver a precise amount of lubricant to the bearing to be lubricated. to

the bearings that need to be lubricated, thereby minimizing friction and operating temperatures.

Oil-air lubrication systems offer the following advantages:

Increase of the reachable speed of the bearings

Reduced frictional torque and energy consumption

Reduced environmental impact

Reduced lubricant consumption

Maximized lubrication effectiveness

Moderate pressure in the bearing housing prevents the ingress of contaminants

Lower Operating Temperature

SKF conducted a temperature rise test comparing the Ultra Precision Bearing Lubrication Unit with

other commonly used similar products. High-speed test results show that the Ultra precision bearing

lubrication unit can reduce operating temperatures by 10-15%.

Ultra-precision bearing lubrication units extend bearing life and increase operating speed for

high-speed operating applications such as machining centers, milling machines, internal ring

grinders, and spindles where spindle drilling for printed circuit boards is required.

This unit runs on high speed spindles with an oil and gas lubrication system in both horizontal

and vertical positions.

The SKF ultra-precision bearing lubrication unit consists of a set of precision paired spacers

and an ultra-precision high-speed single-row angular contact ball bearing with a 15° or 18°

contact angle. contact ball bearing (belonging to the 70.... E series/ISO 10 diameter series).

Suitable shaft diameters range from 30 to 70 mm.

All-steel bearings with balls made of steel rings and bearing grade silicon nitride and hybrid

ceramic bearings are available. Since silicon nitride (ceramic) bearing balls are much lighter

and stiffer than steel balls, hybrid ceramic bearings can provide higher rigidity and much

faster rotation than all-steel bearings.

SKF Ultra Precision Bearing Lubrication Units are designed for the following 70.... E

series bearing configurations:

A single general purpose paired bearingOne tapered roller bearing in a tandem configuration

One tapered roller bearing in a back-to-back configuration

The bearing configurations can be of various types:

Single or tandem configurations with spring preload, back-to-back configurations with

compact preload.