- Location:

- Home

- Products

- Carbon fibre components

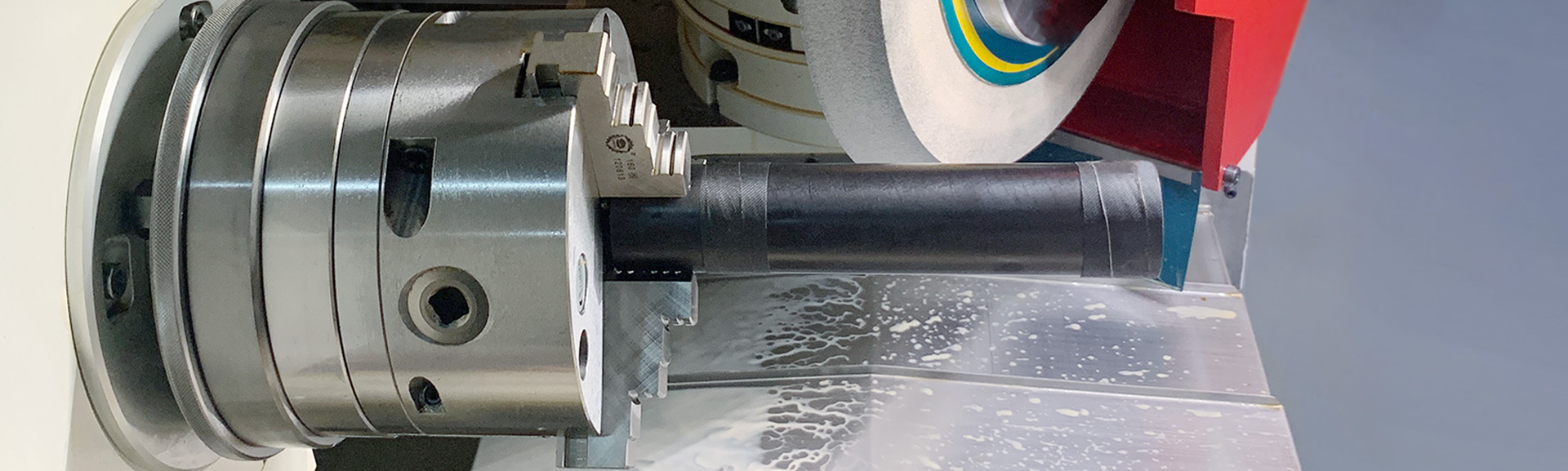

German process carbon fibre ultra-high speed CFRP rotor sheath

Rotor design for surface-mounted high-speed permanent magnet synchronous motors

Synchronous high-speed permanent magnet motors are characterised by high power density, small

size and high efficiency, and are increasingly used in many applications where high speed is required.

In order to To effectively ensure that the permanent magnets (magnets) of the rotor of high-speed

motors work safely and normally at high speeds, they need to be fixed in a reasonable way. Based on

many years of of practical applications, the use of carbon fibre composite materials, through rational

calculations and process design, is a more ideal solution.

The tensile strength and stiffness of carbon fibre composites is three to five times greater than that of

conventional metallic materials (e.g. steel, aluminium, titanium, etc.); at the same time, carbon fibre

composites are far more elastic in their The allowable strain in the elastic range of carbon fibre

composites is much greater than that of most metallic materials. The following graph compares

the strength performance curves of carbon fibre materials with those of several other materials.

For motor rotors, the magnets (permanent magnets) can be designed to be fixed to the outer surface of the

rotor, usually in one of two ways: either with the common magnets embedded or by attaching the magnets to

the outer surface of the rotor using an adhesive material; however, in either case, there is a high risk of the

magnets being thrown off by the centrifugal force generated by the rotor rotating at high speed. However, in

either case,there is a high risk of the magnets being thrown out by the centrifugal force of the rotor rotating

at high speeds; this therefore limits the motor from achieving the desired high speed. On the other hand, the

Even if the magnets are not completely thrown out of the rotor at high speeds, the very small displacements

caused by the high centrifugal forces may The entire dynamic balance of the rotor can be disrupted, resulting

in significant motor failure or even danger.

The use of a carbon fibre rotor sleeve solves this problem by wrapping the magnets in a carbon fibre sleeve

and applying a precise preload to the sleeve and magnets. This allows the rotor to operate safely and effectively

at high speeds.

In principle, it is also possible to use metallic materials to wrap the magnets, but due to the properties of the

metallic material itself, when the rotor rotates at high speed to generate a magnetic field, eddy current losses

are generated on the surface of the metallic material and weaken the power of the motor and generate

additional heat, resulting in superimposed losses. Due to the properties of the metal material, eddy current

losses are generated on the surface of the metal material when the rotor rotates at high speeds to generate

a magnetic field, which reduces the power of the motor and generates additional heat, thus increasing the

rotor temperature and causing superimposed losses, or for which a separate cooling system is required.

A separate cooling system is required for cooling. Alternatively, non-magnetic metallic materials can be

used to wrap the magnets, but these materials are more expensive and have no advantage over carbon fibre.

This material has no advantage over carbon fibre.

In addition, for more demanding applications, the carbon fibre material can be laminated in different ways to

achieve the most convenient process, which is not possible with other materials. This is not possible with other

materials.

The following parametric information is required for a carbon fibre rotor design solution.

Rotor construction and the maximum and rated rotor speed

Structural dimensions and density of the magnets

Air gap of the stator and rotor

The temperature at which the motor will operate, etc.

In general, the above parameters will help us to better design the carbon fibre sleeve. The thickness

of the carbon fibre sleeve must match the thickness between the magnet and the coil The air gap

between the magnet and the coil must be matched and the inner diameter of the carbon fibre sleeve

must be smaller than the outer diameter of the magnet in order to create sufficient preload and thus

protect the magnet from being thrown out by centrifugal forces. For special cases where the carbon

fibre sleeve is subjected to greater loads, we have, through many years of experience, added a

protective layer to its surface, with the aim of protecting the overall structure of the carbon fibre The

purpose of this is to protect the overall structure of the carbon fibre sleeve, for example, from damage

caused by knocks during assembly, which may destroy the stress distribution of the entire carbon fibre

sleeve.

We do not recommend that customers rework the carbon fibre sleeves at a later stage as this can lead

to the destruction of the stresses within the carbon fibre composite, which can cause the carbon fibre

to separate and ultimately cause the whole carbon fibre sleeve to be separated. This can lead to the

separation of the carbon fibres and ultimately to the failure of the entire carbon fibre sleeve structure.

We have many years of practical experience in Europe with carbon fibre composites, high speed precision

rotating applications and have supplied high end customers such as manufacturers of high speed motors,

high speed centrifugal molecular We have many years of practical experience in Europe with carbon fibre

composites and high speed precision rotating applications. We hope that our services will add value to your

products. We are always looking forward to it.