- Location:

- Home

- Products

- UNCOATED TEXTILES

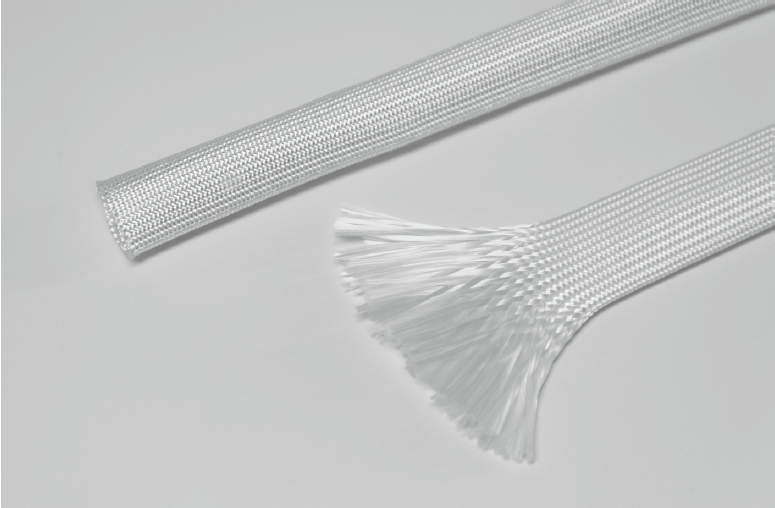

GLASFLEX

GLASFLEX is a product formed by intertwining multiple glass fiber yarns with a specific braiding angle through circular braiders. Such formed seamless textile tube is flexible and can be expanded to fit on a wide range of hoses. Depending on the braiding angle (gener-ally between 30º and 60º, the material density and the numbers of yarns, different constructions can be obtained.

GLASFLEX is produced with textile sizing which is compatible to most of the coating material such as, but not limited to, silicone varnishes, polyurethane, acrylic and epoxy resins, PVC based formulations and many more…

Fiberglass yarns belongs to inorganic material with high content of SiO2, which makes it extremely resistant to high temperatures. The material itself has melting point of above 900 ºC.

Technical Overview | |||

MaxWorkingTemperature | Sizing: | Applications | |

-55°C , +350°C | Paraffin sizing | Electric Motor insulation | |

Silane sizing | Thermal insulation | ||

Starch sizing | Mechanical resistance | ||

| Material: | Applications: | ||

| E-Glass | Electric insulation sleeve | ||

| Construction: | Mechanical protection sleeve | ||

| Braided | |||

Dimensions | ||

Size | ID/ Nom. D | Max ID |

GL- 6 | 6mm | 10mm |

GL- 8 | 8mm | 12mm |

GL- 10 | 10mm | 15mm |

GL- 12 | 12mm | 18mm |

GL- 14 | 14mm | 20mm |

GL- 18 | 18mm | 25mm |

GL- 20 | 20mm | 30mm |

- Contact

- tel:+86 (010) 85999278

- Email:service@bonsing.com

- Address:1 Futong East Ave, 100123 Beijing, China